In today’s competitive manufacturing industry, pipe extrusion machines are the backbone of plastic pipe production. Whether it’s PVC, HDPE, or PPR pipes, the quality of extrusion machinery directly impacts strength, durability, and production efficiency.

But here’s the big question most Indian manufacturers face:

👉 Should you invest in imported pipe extrusion machines or choose a Made-in-India machine?

At JJ Industries India, we work closely with manufacturers across the country and have seen the real challenges businesses face when choosing between imported and Indian extrusion machines. This blog will give you a detailed comparison to help you make the right investment.

What Makes a Pipe Extrusion Machine So Important?

A pipe extrusion machine is not just equipment—it’s the heart of your production line. Its efficiency determines:

– Pipe Quality → Pipes must meet industry standards for pressure, durability, and safety.

– Production Speed → A machine that runs smoothly reduces delays and boosts output.

– Cost of Operations → Energy consumption and maintenance costs affect overall profitability.

– Downtime Management → Quick repairs and reliable service mean less production loss.

Imported Pipe Extrusion Machines: Pros and Cons

Many businesses in India import machines from countries like China, Germany, or Taiwan. These machines come with certain advantages but also hidden challenges.

Advantages of Imported Machines

– Advanced Features: Some imported brands offer high-tech automation and modern designs.

– High-Speed Output: Premium machines can sometimes deliver higher production rates.

– International Branding: Machines from Europe or Japan carry a reputation for quality.

Disadvantages of Imported Machines

1. High Initial Investment – Prices skyrocket due to shipping, taxes, and currency exchange rates.

2. Difficult Service & Maintenance – Technical support and spare parts take weeks or even months.

3. Limited Customization – Machines are made for global markets, not Indian-specific needs.

4. High Downtime Risk – If a machine breaks down, production halts until service is available.

5. Slow ROI (Return on Investment) – With high costs and delays, it takes longer to recover investment.

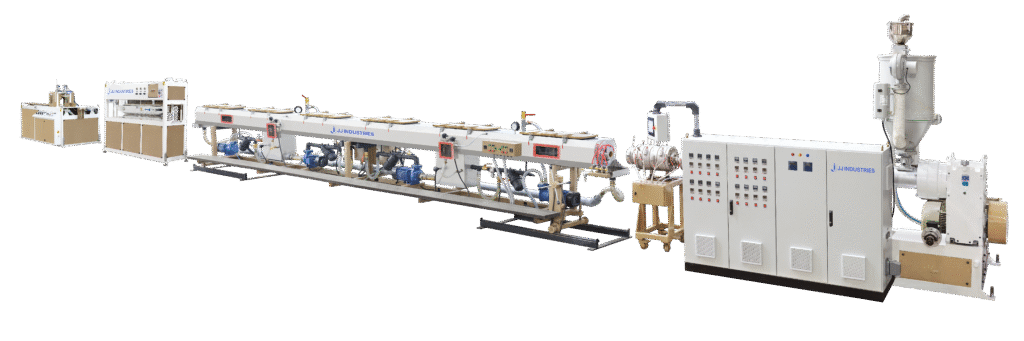

Made-in-India Pipe Extrusion Machines: The JJ Industries Advantage

Over the last decade, Indian manufacturing companies like JJ Industries India have transformed the extrusion industry. Instead of relying on expensive imports, Indian businesses now have access to world-class extrusion machines at affordable prices

Advantages of JJ Industries’ Made-in-India Machines

1. Cost-Effective Investment – Significantly lower price compared to imported machines.

2. Reliable After-Sales Support – Quick service and local spare parts availability.

3. Tailor-Made Solutions – Machines designed according to your production requirements.

4. Durable & Efficient – Built with high-quality components for long-term use.

5. Optimized for Indian Conditions – Handles voltage fluctuations, local raw material, and long production cycles.

6. Faster ROI – Affordable pricing and reliable service ensure businesses recover costs quickly.

7. Make-in-India Contribution – Choosing local machines supports India’s self-reliant manufacturing ecosystem.

Detailed Comparison: Imported vs Made-in-India Machines

| Feature | Imported Machines | JJ Industries (Made-in-India) |

| Investment Cost | Very High (shipping, duty) | Affordable & budget-friendly |

| After-Sales Support | Delayed, costly | Quick, local, reliable |

| Customization | Limited | Fully flexible as per client |

| Spare Parts | Difficult to source | Readily available |

| Downtime Impact | Very High | Minimal |

| Production Speed | High, but costly | Competitive, optimized |

| Suitability to India | Limited (foreign settings) | Designed for Indian conditions |

| Return on Investment (ROI) | Slow | Fast |

Why Indian Manufacturers Prefer JJ Industries

Indian manufacturers are now realizing that imported machines may not be worth the hassle. JJ Industries India provides a complete solution that addresses every concern manufacturers face:

– Affordable Excellence → Lower investment, higher returns.

– Quick Service → No weeks of waiting—help is always nearby.

– Trusted Quality → Precision-engineered machines that match international standards.

– Future-Ready Technology → Continuous innovation to stay at par with global competition.

– Customer-Centric Approach → We don’t just sell machines; we build long-term partnerships.

Real-World Example

A mid-sized PVC pipe manufacturer in India faced frequent breakdowns in their imported machine. Spare parts took over 40 days to arrive, causing massive losses. They switched to JJ Industries’ extrusion machine, and now:

– Their downtime is reduced by 80%.

– Spare parts and service are available within 24–48 hours.

– Their ROI improved within just 12 months.

This is the kind of reliability that Made-in-India machines offer.

Why Choose JJ Industries India?

– Proven Expertise – Years of experience in designing and manufacturing extrusion machines.

– Wide Product Range – PVC, HDPE, and PPR extrusion machines for every scale of business.

– Customized Solutions – Every business is unique, and so are our machines.

– Robust Performance – Designed for long hours of uninterrupted production.

– Local Support Network – Easy access to service and spare parts.

– Affordable Pricing – International-level quality at Indian prices.

Frequently Asked Questions (FAQ)

Q1. Are imported extrusion machines always better than Indian ones?

Not necessarily. While some imported machines have advanced features, they are costly, hard to maintain, and not suited for Indian working conditions.

Q2. How is JJ Industries different from other Indian manufacturers?

JJ Industries stands out due to its precision engineering, customer-first approach, and quick service network, which many smaller local brands cannot match.

Q3. What is the lifespan of a JJ Industries extrusion machine?

With proper maintenance, our machines can run efficiently for 10+ years, ensuring long-term returns.

Q4. Can JJ Industries customize a machine for my factory setup?

Yes, we provide tailor-made solutions based on your production capacity, pipe size requirements, and material type.

Q5. How soon can I get spare parts if needed?

Since we are based in India, spare parts are available immediately, unlike imported machines where the wait can be months.

Final Verdict

If you want to avoid unnecessary costs, delays, and service headaches, Made-in-India pipe extrusion machines from JJ Industries are the best investment. Instead of spending huge amounts on imports, choose a machine that is:

✔ Affordable

✔ Reliable

✔ Customizable

✔ Supported Locally

At JJ Industries India, we are committed to delivering world-class extrusion machines designed for Indian manufacturers. JJ Industries India – Redefining Pipe Extrusion Technology with World-Class Made-in-India Machines. Contact JJ Industries today to get the perfect extrusion machine for your business and experience the power of Make-in-India innovation.