The manufacturing industry in India is evolving rapidly, and plastic extrusion machines are playing a crucial role in this transformation. These machines are widely used in industries such as packaging, construction, automotive, and household goods. With advancements in manufacturing technology, businesses are now using modern extrusion machines to improve efficiency, reduce waste, and increase production speed.

In this blog, we will explore how Plastic Extrusion Machines in India are revolutionizing manufacturing, the latest advancements in industrial machinery, and why JJ INDUSTRIES is the best choice for businesses looking for high-quality extrusion machines.

What Are Plastic Extrusion Machines?

A plastic extrusion machine is used to melt plastic and shape it into different products such as pipes, sheets, films, and profiles. The process involves heating plastic material, pushing it through a mold, and cooling it to form the desired shape. This method is highly efficient and allows manufacturers to produce high-quality plastic products in large quantities.

Example:

A packaging company uses plastic extrusion machines to create plastic film rolls for making shopping bags and food packaging. With an advanced extrusion machine, they can produce more film in less time, reducing costs and increasing profit.

Growing Demand for Plastic Extrusion Machines in India

Why Are These Machines in High Demand?

- Expanding Industries: Plastic is used in multiple industries, including construction, healthcare, and electronics.

- Increased Production Needs: Businesses need faster and more reliable machines to meet growing consumer demands.

- Eco-Friendly Options: Many manufacturers are looking for energy-efficient and recyclable plastic extrusion solutions to reduce environmental impact.

Example:

A construction company needed durable PVC pipes for plumbing systems. By investing in a high-quality extrusion machine, they were able to produce their own pipes instead of purchasing them from a supplier, saving money and ensuring better quality control.

Key Advancements in Plastic Extrusion Machinery

1. Automation and Smart ControlsModern extrusion machines come with computerized controls that allow manufacturers to monitor and adjust settings in real-time. This reduces errors and improves efficiency.

2. Energy-Efficient Technology

New machines are designed to consume less electricity while maintaining high performance. This helps businesses save money on energy costs.

3. Improved Material Usage

With advanced technology, manufacturers can reduce plastic waste and ensure consistent product quality.

Example:

A toy manufacturing company switched to an automated extrusion machine, reducing production time by 40% and minimizing material waste, leading to higher profits.

Types of Plastic Extrusion Machines and Their Uses

- Single-Screw Extrusion Machines – Used for making pipes, sheets, and films.

- Twin-Screw Extrusion Machines – Ideal for complex plastic products, such as plastic composites and color mixing.

- Blown Film Extrusion Machines – Used for plastic bags, shrink wrap, and packaging film.

- Profile Extrusion Machines – Best for window frames, door profiles, and plastic furniture parts.

Example:

A furniture manufacturer started using a profile extrusion machine to make high-quality plastic chair frames. This allowed them to create durable, lightweight, and cost-effective furniture at a faster rate.

How Plastic Extrusion Machines Improve Manufacturing Efficiency

- Faster Production Cycles – Machines can produce large volumes of plastic products quickly.

- Lower Production Costs – Less material waste and energy consumption mean lower expenses.

- Better Product Quality – Advanced machines ensure precision and consistency in product design.

Example:

A plastic bottle manufacturer upgraded to a high-speed extrusion machine, allowing them to produce 20% more bottles per day without increasing operational costs.

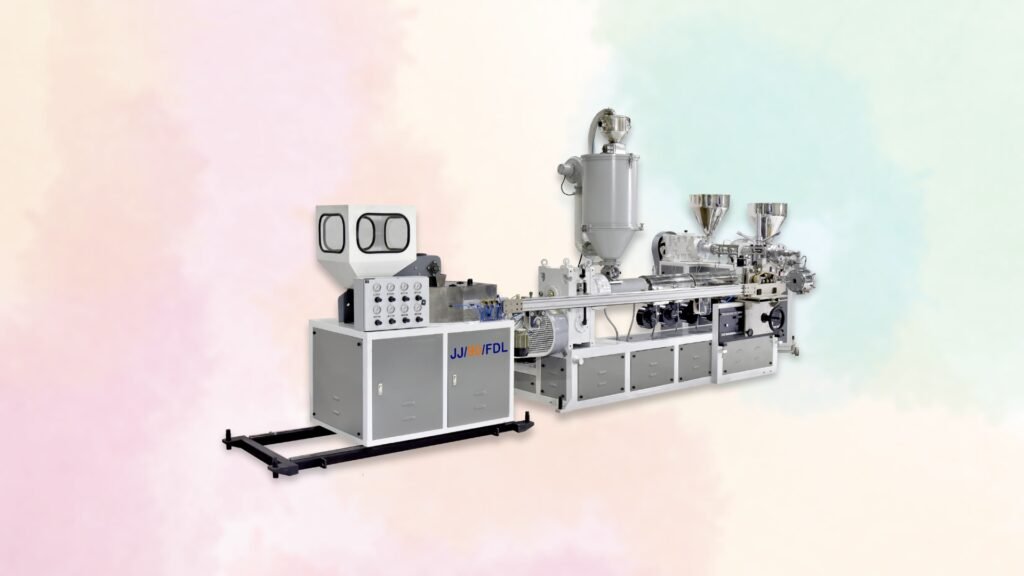

Why Choose JJ INDUSTRIES for Plastic Extrusion Machines in India?

If you’re looking for the best plastic extrusion machines in India, JJ INDUSTRIES is your go-to provider. Here’s why:

- Cutting-Edge Technology: Our machines are equipped with automation and energy-saving features.

- Custom Solutions: We offer tailor-made machines to suit different manufacturing needs.

- Durability & Precision: Our machines ensure high-quality and consistent output.

- Reliable Support: We provide installation, training, and after-sales service to help businesses succeed.

Example:

A small-scale plastic sheet manufacturer partnered with JJ INDUSTRIES and upgraded their old machinery. As a result, they saw a 50% increase in production capacity, helping them expand their business.

Conclusion

Plastic Extrusion Machines in India are transforming the manufacturing sector by improving efficiency, reducing costs, and enabling businesses to scale up. With advancements in manufacturing technology, investing in the right extrusion machine is crucial for long-term success.

For businesses looking to upgrade their plastic manufacturing processes, JJ INDUSTRIES provides top-quality plastic extrusion machines that deliver superior performance and reliability.

Call to Action

Ready to take your manufacturing to the next level? Contact JJ INDUSTRIES today for the best plastic extrusion machines in India and experience the future of manufacturing!